We are a professionally trained and certified full-service electrical company with deep expertise in industrial automation and control systems. Our specialties include electrical automation, facility-wide robotics integration, preventative and corrective machine maintenance, safety automation systems, and modernization of legacy equipment. We are industry leaders in the design and implementation of centrifuge control panels and proprietary software, delivering high-performance solutions that optimize reliability, safety, and efficiency across a wide range of industrial applications.

We design automation systems that bring full visibility and control to your facility operations. From centralized SCADA integration to smart PLC-based monitoring of pumps, motors, and process equipment, our facility automation solutions reduce downtime, improve energy efficiency, and streamline operations across industrial environments.

Safety is not an afterthought—it’s engineered into every system. Our safety automation solutions include integrated emergency shutdown (ESD) systems, interlocks, fail-safe controls, and real-time monitoring to meet compliance standards and protect both personnel and equipment in high-risk environments.

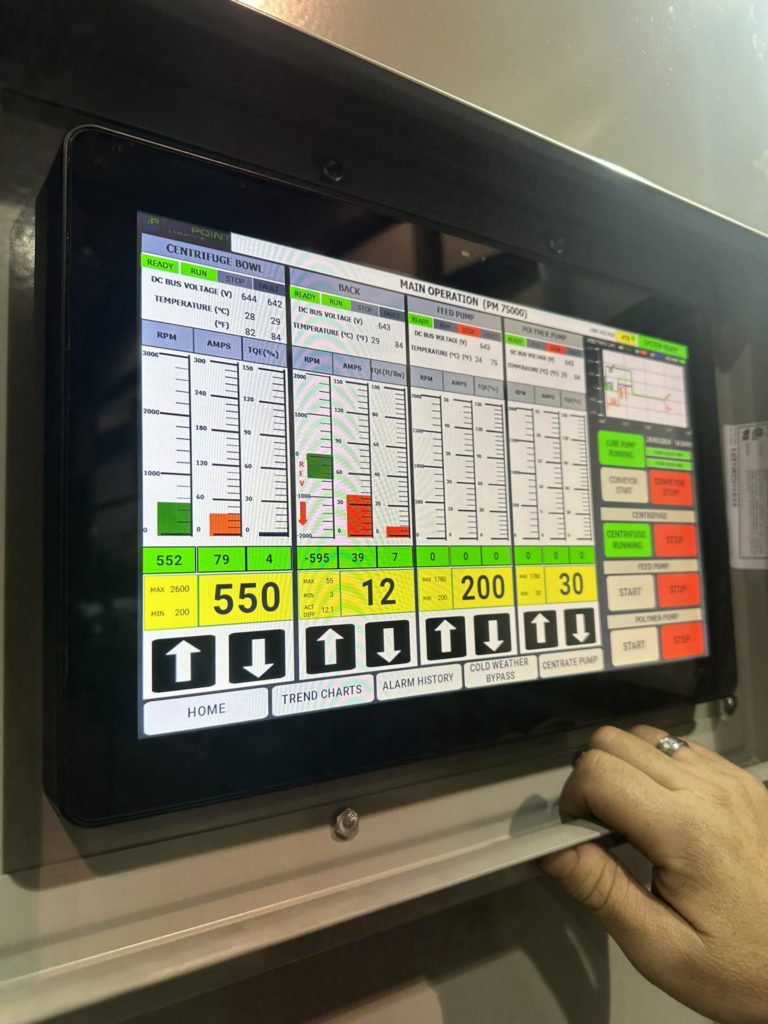

Our machine automation systems are built to optimize performance, precision, and repeatability. Whether controlling centrifuges, conveyors, or batching systems, we deliver custom control panels with advanced logic, sensor integration, and HMI interfaces—designed for high-efficiency, operator-friendly control.

As a COR-recognized company (Certificate of Recognition), we adhere to rigorous safety management standards across all phases of design, manufacturing, and on-site commissioning. Our control systems are built to meet or exceed applicable electrical and process safety codes, and our team follows detailed procedures to ensure hazard mitigation, lockout/tagout compliance, and safe system integration.

Technology Transfer Inc. designs and manufactures high-performance centrifuge control panels engineered for precision process control, system integration, and long-term reliability. Our panels feature advanced PLC-based automation, VFD motor control, touchscreen HMIs, and real-time monitoring capabilities tailored to decanter and disc-stack centrifuge systems. Serving industries such as oil & gas, wastewater treatment, mining, and food processing, we specialize in both custom-engineered solutions and standardized systems—ensuring seamless integration with existing infrastructure, enhanced safety protocols, and optimized separation performance across a wide range of operational environments.

At the core of our control systems is Technology Transfer Inc.’s proprietary centrifuge control software—developed in-house to provide advanced process automation, precision control, and real-time diagnostics. Designed specifically for decanter and disc-stack centrifuges, the software integrates seamlessly with PLCs and HMIs to manage parameters such as bowl speed, feed rate, torque load, differential speed, and vibration thresholds. Built with flexibility in mind, it supports multiple operational modes, customizable alarm logic, and comprehensive data logging for performance analysis and remote troubleshooting. Our software enables operators to fine-tune separation processes with unmatched accuracy, while reducing downtime and maximizing throughput.

Technology Transfer Inc. specializes in the design and fabrication of custom centrifuge control systems tailored to meet the exact requirements of each application. Whether retrofitting an existing skid or building a new turnkey solution, our engineering team works closely with clients to develop panels that integrate seamlessly with plant infrastructure, process specifications, and equipment standards. Every system is built in-house to ISO 9001 quality standards and includes detailed schematics, PLC programming, and FAT-tested functionality prior to delivery. Our custom panels are engineered for durability, reliability, and optimal process control in demanding environments.